[Event Report] Taipower - ECCT LCI Workshop Series 7: PV Panel Recycling Practices & Solutions

The ECCT's Low Carbon Initiative (LCI) and Taipower’s Taiwan Power Research Institute (TPRI) together arranged an online workshop on the subject of solar photovoltaic panel recycling practices and solutions. At the event welcome remarks were made by Shen Teh-Chen, Deputy General Manager of Taipower's Taiwan Power Research Institute (TPRI, 台電綜合研究所副所長 沈德振) and Eric Yu, ECCT LCI Vice Chair, while presentation were given by Hsi Chih-lun, Deputy Director-General of the Department of Waste Management, under the Environmental Protection Administration (EPA, 行政院環保署廢管處副處長 許智倫); Lai Chiou-chu, Deputy General Director, Material and Chemical Research Laboratories from ITRI (工研院材料與化工研究所副所長 賴秋助); Fan Hsin-hsin, Commercial Engineer from ROSI Solar ( 商業工程師 范馨心) and Kevin Chen, Director, Government and Infrastructure Advisory from KPMG Advisory Services (安侯企業管理股份有限公司顧問部副總 陳俊賓). This workshop was attended by over 90 people online.

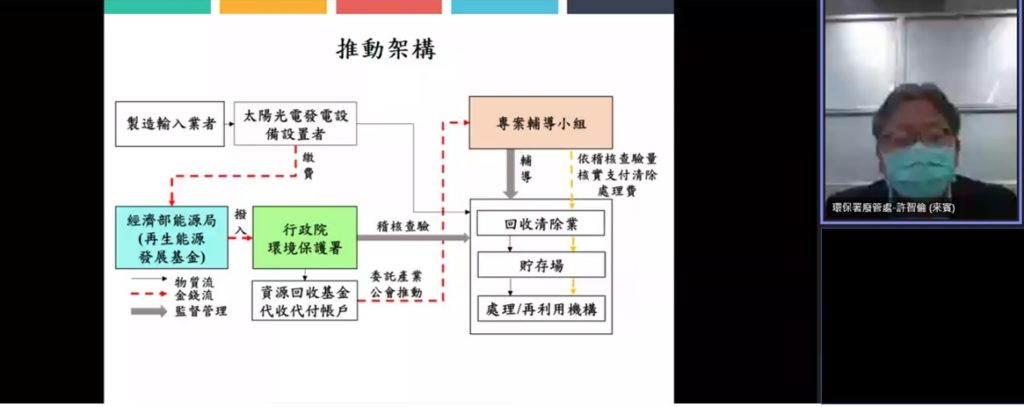

In his presentation, Hsi Chih-lun, spoke about the recycling and processing mechanism for solar panels. To reduce carbon emission in PV module recycling and material reuse, Hsi mentioned the EPA will include incentives in the recycling regulation to encourage easy dismantling design of PV panels. Based on Taiwan's target of 20GW of solar energy by 2025 and the expected lifespan of solar panels, it is estimated that the scrap volume could reach up to 10,000 metric tons by 2032 and 100,000 metric tons from 2039 and much higher annual volumes after that.

The main materials of solar panels are glass, aluminium, solar cells (made of silicon, copper indium gallium di-selenide (CIGS) or cadmium telluride, (CdTe), and plastic). The recycling process requires removing the aluminium frame, separating the various layers of glass, silicon and other before crushing or heating and then sorting each metal substance.

A waste solar panel recycling, removal and processing information system (PVIS) was set up in October 2019 with the purpose of providing registration for solar PV generation equipment installers, recycling information and equipment registration database, various audit query data and statistical management functions. The owners of solar power plants are responsible for dismantling waste solar photovoltaic panels. The speaker outlined the rules of handling, storing and transporting waste materials.

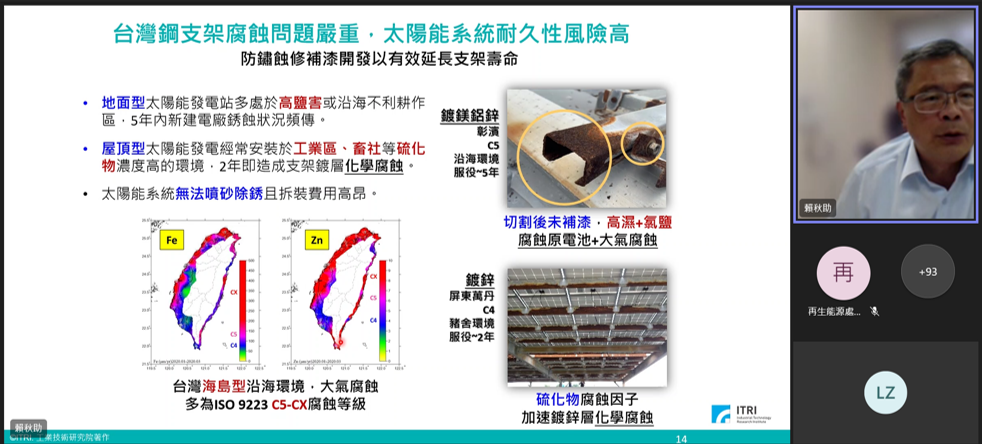

In his presentation, Lai Chiou-Chu, spoke about PV module redesign for recycling. He noted that 50% of the carbon footprint of solar panels are from the mining and processing of silicon to make silicon wafers and solar cells while the next highest contributor is the glass panel. Emissions from aluminium frames and other components are relatively low.

Since it is difficult to separate the various layers of components due to the strong adhesion of the encapsulant, crushing panels is still the mainstream method of disposing of solar panels. Given that the materials are mixed with each other after being broken down, they can only be used for slag making in steel furnaces or as floor tiles. ITRI has developed an innovative easy-to-disassemble PV module comprising EVA/TPE composite encapsulant and a dismantling process. ITRI's circular economy approach changes the packaging material design and uses thermal cracking to separate the cell and glass. In so doing, it changes the existing PV decommissioning recycling path to one that realises the value of recycled products. This is considerable since, according to ITRI's estimate, the raw material cost of 1GW silicon module material is about NT$4.8 billion, while there is also considerable value to be realised if complete glass plates can be refurbished/reused and solid silver wire can be easily extracted.

The speaker went on to describe new PV panel designs that would make them easy to disassemble so that the materials could be reused or recycled. Under ITRI's design, undamaged glass plate and high purity silicon wafers could be reclaimed along with ribbon and silver wire. The value of reclaimed products surpasses those from commercial modules significantly. Moreover, the use of re-generated silcon wafers and crystal growth material can reduce the carbon emissions by 52% and 42%, respectively.

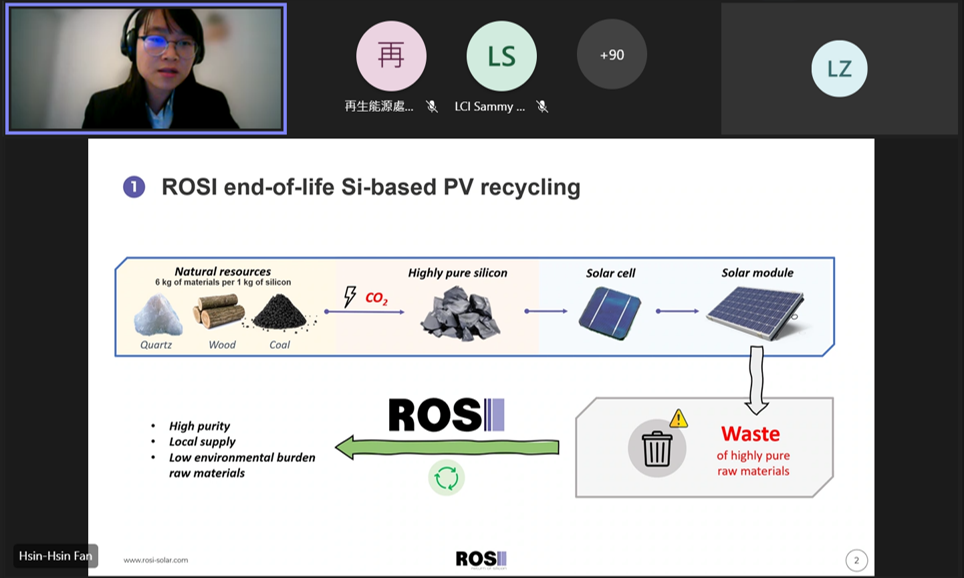

In his presentation Fan Hsin-hsin, introduced his company's high-grade PV module recycling technology for resource recovery. According to the speaker, the company's unique process is able to extract aluminium frames, junction box and cables, high transparency glass cutlets, copper ribbons, high purity silicon chips (99.999% purity) and silver. Compared with current processes, which recycle 35% of materials, ROSI is able to recycle 95%. This results in considerable CO2 emission reductions since every 1kg of modules recycles prevents 2kgs in carbon emissions, according to Fan.

Progress in Europe has happened because of a strong legislative framework in the EU. Since 14 February 2014, the collection, transport and treatment (recycling) of photovoltaic panels has been regulated in every single EU country. Rules require the producers of PV panels to ensure the take-back and recycling, including the related administration, reporting and financing - of their products within the EU member states. As solar panels reach the end of their useful lives, this will also create a business opportunity for companies like ROSI since, according to estimates one million tons of accumulated PV modules will be collected and recycled across Europe by 2025 and this will rise to 10 million tons by 2050.

In his presentation, Kevin Chen, Director, Government and Infrastructure Advisory from KPMG Advisory Services, spoke about waste recycling and treatment business in Taiwan. He gave an overview of solid waste output and disposal methods, which types of waste have to be recycled and common disposal methods.