ECCT LCI: Forum on green energy storage in smart grids

28 March 2014, Sheraton Hotel, Hsin-chu

The ECCT's Low Carbon Initiative (LCI) teamed up with the Taiwan branch of SEMI, the global industry association serving the manufacturing supply chain for the micro- and nano-electronics industries, to host a forum on the subject of green energy storage and smart grid development. The forum featured three speakers from among LCI members: Siemens, BASF and Schneider Electric, and as well as speakers from SEMI, the Industrial Technology Research Institute (ITRI) Phoenix Silicon International Corporation and PV Taiwan, the Taiwan International Photovoltaic Exhibition for Energy/ Green Power, Green Energy industry.

The event photos are now at ECCT FB. The IC Broadcasting Station also introduced the event on 31 March 2014:![]()

The full coverage of the event including presentation slides is as follows:

Downlad the presenters' slides via http://semitw.org/edm.jsp?edm=3723

Topic: Battery storage for solar power plants

Alexander Ott, Head of Segments and Application, Project Management, Motion Control Systems, Siemens

Siemens has already developed good solutions for battery storage that work with both direct current (DC) and alternating current (AC) that can be integrated with any kind of energy source including wind, solar, hydro, biogas or traditional power plants. The company has three large projects in Germany and other countries, such as Greece, where the company has set up a completely stand-alone, independent system that provides power 24 hours a day that is completely powered by renewable energy. The main problem with renewable energy is that it is not constant. While photovoltaic (PV) power is clean, the problem is how to provide power at night when the sun is not shining.

Meanwhile, energy generated by wind is unstable and intermittent. For this reason, traditional power plants have needed to be kept running on stand-by mode, even during the day in case the wind stops blowing. Siemens has solved both of these problems by using an energy storage system as a buffer. The optimal combination of power electronics based on lithium-ion batteries ensures a stable and reliable power supply. While the energy storage industry is still in its infancy, demand is growing rapidly and the potential is enormous. According to Ott, battery storage sales are already growing 25% every quarter. The efficiency rate is 98%, the return on investment of less than three years and lithium-ion batteries should last 20 years.

Topic: Chemistry powers energy

Speaker: Pierre Chang, Sr. Manager, Sales Inorganics Business, BASF

While BASF is a chemical and not a technology company, it understands the needs of the technology industry and has the right materials to supply the technology industry. Demographic changes have set the stage for the future of the chemical industry. We need to change our way of life to sustain the world's expected population of nine billion people by 2050 in terms of resources, environment and climate, food and quality of life. The increasing share of renewables in the energy supply increases the volatility, time and amount of surplus energy and drives the need for flexibility to ensure a stable supply of electricity. Batteries therefore are a key element of BASF's energy portfolio.

The company aims to become the world's leading system supplier of functional materials for high-performance batteries. Research and development activities combined with acquisitions have delivered a unique technology portfolio including cathode materials and electrolytes for lithium-ion batteries, as well as licensing nickel metal hydride technology. The company is working with partners in industry and science to develop materials and technologies for current and next generation lithium-ion batteries as well as for future battery systems. The main growth and technology fields for chemistry-based innovations are transport, agriculture, construction, energy, consumer goods, electronics, health and nutrition.

BASF provides materials for batteries for electric vehicles, consumer electronics and stationary applications, e-power management such as organic photovoltaics, high temperature superconductors and stationary storage. The company is making constant advances to improve the quality of its products to improve the performance and endurance of batteries.

Topic: Advanced distribution management systems (ADMS) in smart grids

Speaker: Dr. Raymond Ko, Senior Manager of Energy Business, Schneider Electric

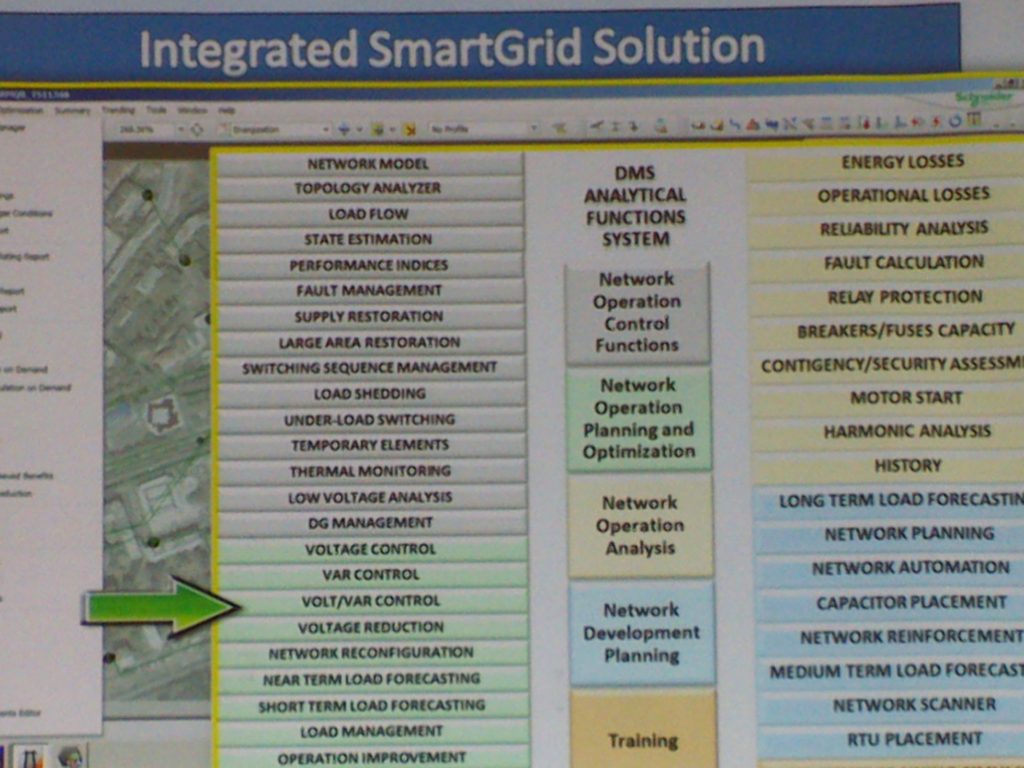

Given the challenge of achieving increased reliability of distributed renewable generation and energy storage, Schneider has developed a comprehensive array of products and solutions. Advanced distribution management systems (ADMS) implies smart generation, smart metering and smart consumption of electricity. Smart grids are needed to integrate renewable energy safely. Schneider offers real time network management solutions which include monitoring, analysis, control, optimization, planning, and training tools that all function on a common distribution network.

The company provides an integrated system combining distribution management (DMS), outage management (OMS), and supervisory control and data acquisition (SCADA) systems into one secure, unified solution with more than 50 advanced functions. This maximizes the benefits possible from a growing foundation of intelligent grid devices, distributed renewable energy, advanced metering, and all things related to the smart grid. The SCADA platform is designed with open and secure architecture, so it interfaces with existing network data collection and control systems and enterprise business processes. It scales as the network expands, and it accommodates new, custom applications as needed. Schneider has developed gas insulated switchgears (GIS), designed as compact units, and built as the union of modular switchgears for wind power. They are specifically designed to meet all the needs of networks up to 36 kV, inside wind farms. The company's DVCAS switchgears can be installed in wind farms up to 2,000 metres above sea level.