ECCT LCI: Bayer's interview with IC Broadcasting Co.

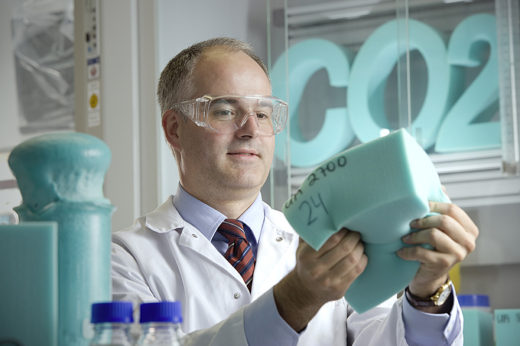

On 14 July, Dr. Robert Chang from Bayer MaterialScience received an interview from Wim Chang, Deputy Executive Director of Delta Electronics Foundation as well as the DJ of IC Broadcasting Co., talking about Bayer's using CO2 instead of petroleum for plastics production, transforming carbon dioxide from climate pernicious to precious material.

Dr. Chang shared how Bayer discovered new avenues to turn the greenhouse gas carbon dioxide into a useful raw material that can replace petroleum as a building block for plastic. The company has joined forces with partners to initiate a number of projects for this purpose. The first CO2-based foams are scheduled to be launched on the market beginning in 2016...

However, many other types of plastics could be manufactured in the long term?

Oil makes the world go around. This fossil resource drives cars and aircraft, is a basic ingredient in many drugs and is found in practically all plastics. But the price of oil is on the rise and reserves are limited. However, something else that we have in abundance can be used instead – carbon dioxide. This waste gas has something in common with oil: It contains the element carbon, a central building block for the chemical industry.

The Dream Production project has come a long way towards turning CO2 into a new raw material. In conjunction with partners from industry and science, Bayer has developed a process to manufacture a key component of high-grade polyurethane foam using carbon dioxide. This is found in many everyday items such as cars, furniture, shoes and insulation.

High quality

The new material has already been tested extensively at a pilot plant in Leverkusen, Germany, which Bayer has had in operation since early 2011. This involved using high-purity CO2 from the energy industry. The new CO2-based foam has at least the same high quality as one made entirely from petroleum by conventional means. It will initially be used to make mattresses. Industrial production of the associated precursor is planned for launch beginning in 2016.

The new process only became possible when Bayer researchers involved in the forerunner project, Dream Reactions, found a special catalyst that experts had been seeking in vain for decades. It is required to trigger the reaction and limit the energy input.

An abundance of ideas

However, Bayer also has many other ideas for using CO2 as a new raw material. Use of the climate gas could be coupled with the frequent surpluses of wind power. Such power peaks can be used for the environmentally friendly production of hydrogen, which can then be used in conjunction with CO2 to produce key chemical building blocks. This is the subject of a further pan-industry research project named CO2RRECT.

Bayer is working toward using carbon dioxide to manufacture many different plastics and utilizing these for numerous applications. This reflects the vision of perhaps being able to eliminate the need for oil completely one day.

About Bayer MaterialScience:

With 2012 sales of EUR 11.5 billion, Bayer MaterialScience is among the world's largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, electrical and electronics, construction and the sports and leisure industries. At the end of 2012, Bayer MaterialScience had 30 production sites and employed approximately 14,500 people around the globe. Bayer MaterialScience is a Bayer Group company.